Specification type

The national standard for hexagon socket head screws is GB70-1985. There are many specifications and sizes, including 3 * 8, 3 * 10, 3 * 12, 3 * 16, 3 * 20, 3 * 25, 3 * 30, 3 * 45, 4 * 8, 4 * 10, 4 * 12, 4 * 16, 4 * 20, 4 * 25, 4 * 30, 4 * 35, 4 * 45, 5 * 10, 5 * 12, 5 * 16, 5 * 20, 5 * 25, 6 * 12, 6 * 14, 6 * 16, 6 * 25, 8 * 14, 8 * 16, 8 * 20, 8 * 25. 8 * 30, 8 * 35, 8 * 40, and so on. [1]

hardness

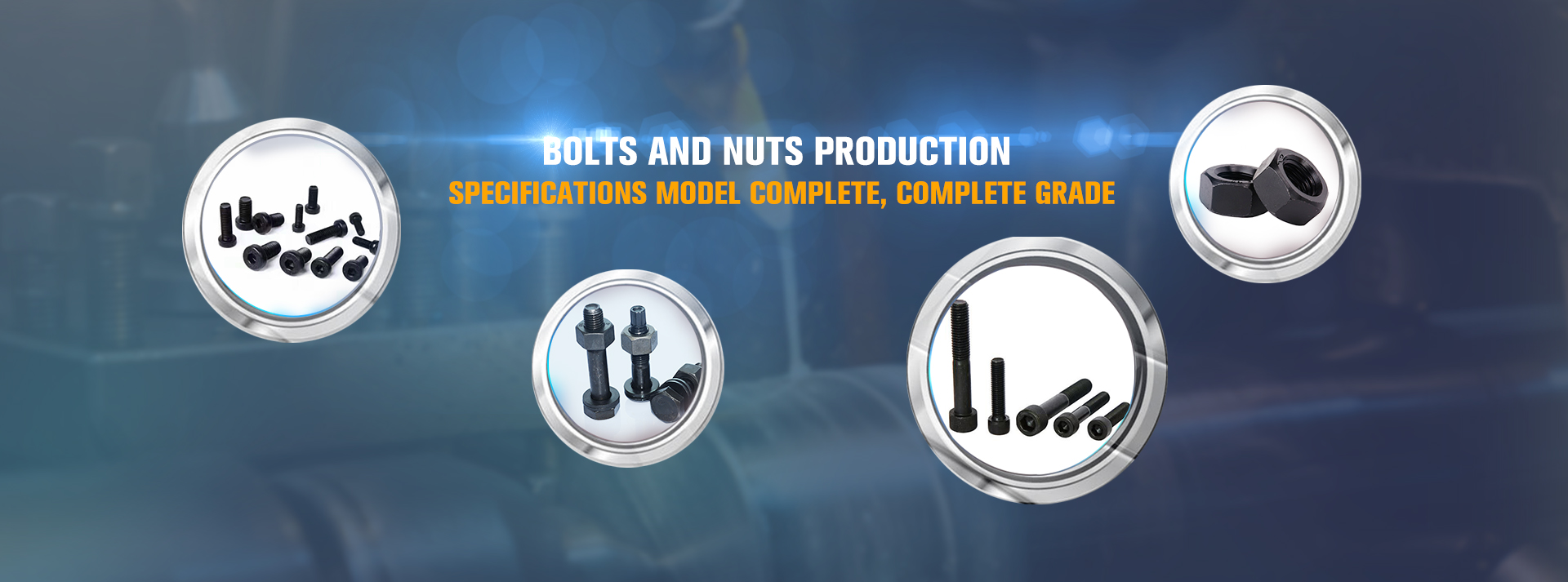

Internal hexagonal bolts are classified according to the hardness, tensile strength, yield strength, etc. of the screw wire, which is the level of internal hexagonal bolts. What is the level of internal hexagonal bolts. Different grades of hexagonal bolts are required for different product materials, and all hexagonal bolts have the following grades:

Internal hexagonal bolts are classified into ordinary and high-strength according to their strength levels. Ordinary hexagonal bolts refer to grade 4.8, while high-strength hexagonal bolts refer to grades 8.8 and above, including grades 10.9 and 12.9. Grade 12.9 internal hexagonal bolts generally refer to black internal hexagonal cup head screws with knurled, natural color, and oil.

Figure 2

The performance grades of internal hexagonal bolts used for steel structure connections are divided into more than 10 grades, including 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc. Among them, bolts of grade 8.8 and above are made of low-carbon alloy steel or medium carbon steel and heat treated (quenched and tempered), commonly referred to as high-strength bolts, and the rest are called ordinary bolts. The bolt performance grade designation consists of two parts of numbers, representing the nominal tensile strength value and yield strength ratio of the bolt material.

Post time: Jun-28-2024